Contents

2.5 LANDSCAPE AND VISUAL Monitoring

2.8 IMPLEMENTATION STATUS OF

ENVIRONMENTAL MITIGATION MEASURES

2.9 Summary of Exceedances of the

Environmental Quality Performance Limit

2.10 Summary

of Complaints, Notification of Summons and Successful Prosecutions

Annex B

ENVIRONMENTAL MITIGATION IMPLEMENTATION SCHEDULE

Annex C

MONITORING SCHEDULE FOR THIS REPORTING PERIOD

Annex D Air

Quality

Annex D1

CALIBRATION CERTIFICATES FOR DUST MONITORING EQUIPMENT

Annex D2

24-HOUR TSP MONITORING RESULTS

Annex D3

EVENT AND ACTION PLAN FOR AIR QUALITY MONITORING

Annex D5

CERTIFICATES OF THE QUALIFIED ODOUR PANELIST

Annex D6

ODOUR MONITORING RESULTS

Annex D8

ambient vocs,

ammonia and h2s monitoring results

Annex E

Noise

Annex E1

CALIBRATION CERTIFICATES FOR NOISE MONITORING EQUIPMENT

Annex E2

NOISE MONITORING RESULTS

Annex E3

EVENT AND ACTION PLAN FOR NOISE MONITORING

Annex F Water

Quality

Annex F1

CALIBRATION CERTIFICATES FOR SURFACE WATER QUALITY MONITORING EQUIPMENT

Annex F2

SURFACE WATER QUALITY MONITORING RESULTS

Annex F3

EVENT AND ACTION PLAN FOR WATER QUALITY MONITORING

Annex F4

CALIBRATION CERTIFICATES FOR EFFLUENT QUALITY MONITORING EQUIPMENT

Annex F5

LEACHATE LEVELS MONITORING RESULTS

Annex F6

EFFLUENT QUALITY MONITORING RESULTS

Annex F7

CALIBRATION CERTIFICATES FOR GROUNDWATER MONITORING EQUIPMENT

Annex F8

GROUNDWATER MONITORING RESULTS

Annex F9

INVESTIGATION REPORTS OF ENVIRONMENTAL

QUALITY LIMIT EXCEEDANCE

Annex G Landfill

Gas

Annex G2

CALIBRATION CERTIFICATES FOR LANDFILL GAS MONITORING EQUIPMENT

Annex G3

LANDFILL GAS MONITORING RESULTS

Annex G4

EVENT AND ACTION PLAN FOR LANDFILL GAS MONITORING

Annex G5

INVESTIGATION REPORTS OF ENVIRONMENTAL QUALITY LIMIT EXCEEDANCE

Annex I

MONITORING SCHEDULE FOR THE NEXT REPORTING

PERIOD

This Monthly EM&A report presents the EM&A works

carried out during the period from 1 to 31 August

2024 for the Project in accordance with the updated EM&A Manual.

No exceedance of Action and Limit Levels for

operation/restoration phase air quality monitoring was recorded in the

reporting period.

No exceedance of Action and Limit Levels for

operation/restoration phase noise monitoring was recorded in the reporting

period.

Two exceedances

of the Limit Levels for groundwater (Ammoniacal-nitrogen and Chemical Oxygen

Demand (COD)) were recorded for water quality monitoring in the reporting

period. The groundwater (Ammoniacal-nitrogen and COD) exceedances at MWX-7 on 5

August 2024 were considered non Project

related upon further investigation.

One exceedance of the Limit

Level for landfill gas (carbon dioxide) was recorded for landfill gas

monitoring in the reporting period. The landfill gas (carbon dioxide)

exceedance at LFG17 on 13 August 2024 was considered non

Project related upon further investigation.

There were no complaints, notification of summons or

prosecution recorded in the reporting period.

There was no reporting change in the reporting period.

Potential environmental impacts arising from the upcoming

construction/ operational activities in the next reporting period of September

2024 are mainly associated with potential

surface water impact in the rainy season.

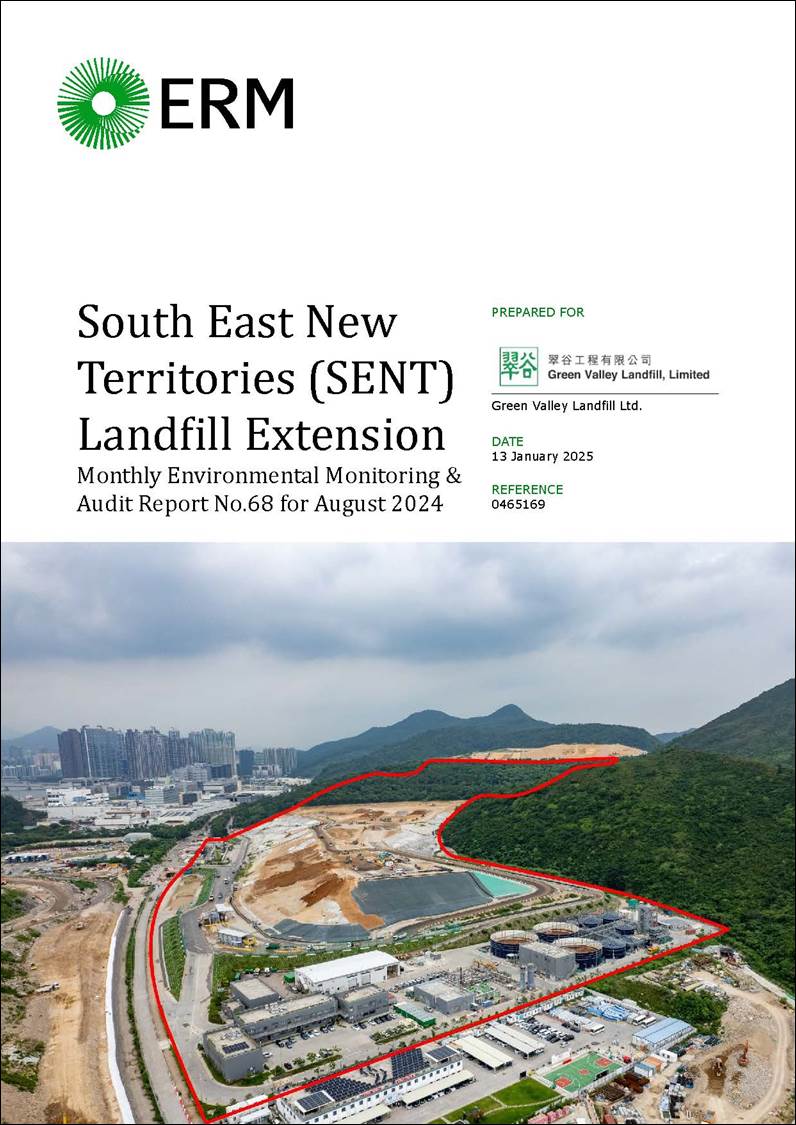

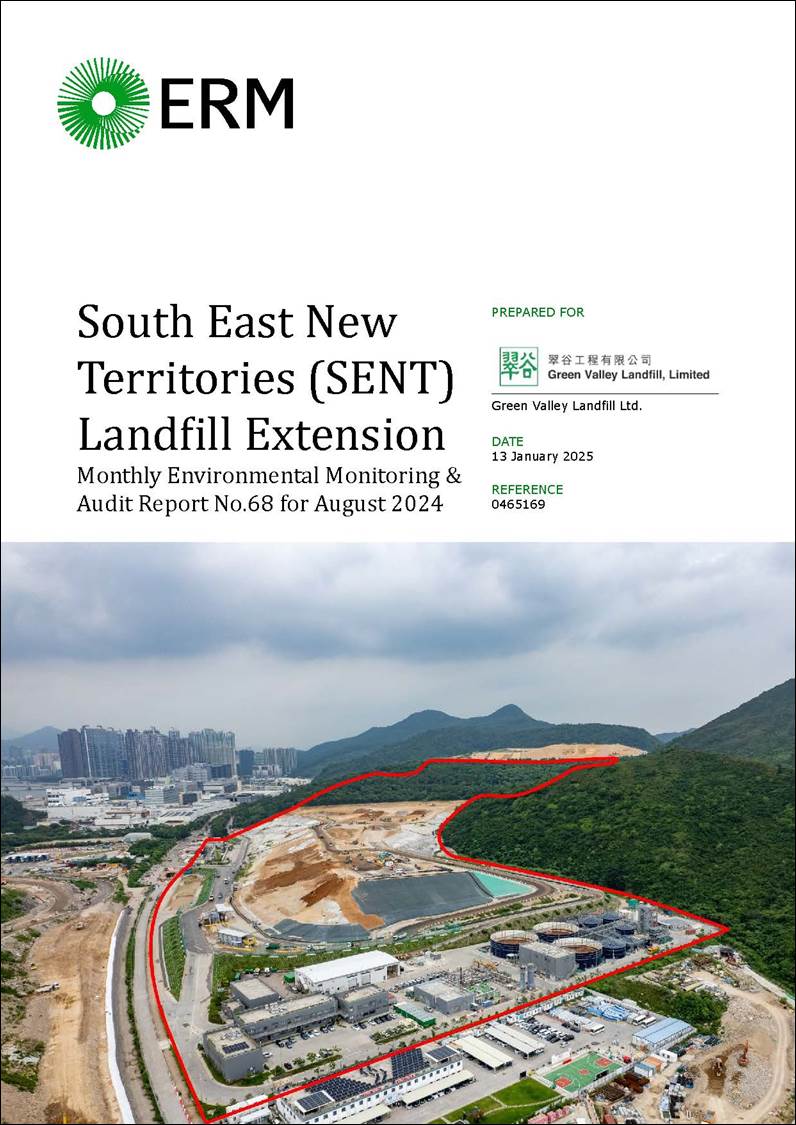

The SENT Landfill Extension (SENTX) forms an

integral part in the Strategic Plan in maintaining the continuity of landfill

capacity in the Hong Kong for the cost-effective and environmentally

satisfactory disposal of waste. The Environmental Impact Assessment (EIA)

Report and the associated Environmental Monitoring and Audit (EM&A)

Manual for the construction, operation, restoration and aftercare of the

SENTX (hereafter referred to as “the Project”) have been approved under the Environmental

Impact Assessment Ordinance (EIAO) in May 2008 (Register No.: AEIAR-117/2008)

(hereafter referred to as the approved EIA Report) and an Environmental Permit

(EP-308/2008) (EP) was granted by the Director of Environmental Protection

(DEP) on 5 August 2008.

Since then, applications for Variation of an Environmental

Permit (No. VEP-531/2017) were submitted to EPD and the Variation of

Environmental Permits (EP-308/2008/A and EP-308/2008/B) were granted on 6

January 2012 and 20 January 2017, respectively, as the Hong Kong SAR Government

has decided to reduce the scale of the design scheme of SENTX assessed in the

approved EIA Report and SENTX will only receive construction waste. In May

2018, a Further Environmental Permit (FEP) (FEP-01/308/2008/B) was granted to

the SENTX’s contractor, Green Valley Landfill, Limited (GVL). In February

2024, VEPs (EP-308/2008/C and FEP-01/308/2008/C) were granted to the

Environmental Infrastructure Division of EPD and GVL, regarding updates on

alternative measures to minimise surface odour emission.

ERM-Hong Kong, Limited (ERM) and Meinhardt Infrastructure

and Environment Limited (Meinhardt) are commissioned to undertake the roles of

Environmental Team (ET) and the Independent Environmental Checker (IEC),

respectively, to undertake the EM&A activities for the Project in

accordance with the requirements specified in the EP, updated EM&A Manual ([1]),

approved EIA Report ([2]) taking

account of the latest design and other relevant statutory requirements.

The SENTX is a piggyback landfill, occupying the southern

part of the existing SENT Landfill (including its infrastructure area) and 13

ha of Tseung Kwan O (TKO) Area 137. A layout plan of the SENTX is shown in Figure 1.1. Under the latest

design, the SENTX has a net void capacity of about 6.5 Mm3 and

provides an additional lifespan of about 6 years, commencing operation upon

exhaustion of the SENT Landfill. The SENTX will receive construction waste

only.

The key implementation milestones of the Project are

indicatively summarised in Table 1.1. The

construction works and operation of the Project commenced on 2 January 2019 and

21 November 2021, respectively.

Table 1.1

Estimated Key Dates of Implementation

Programme

|

Key Stage of the Project |

Indicative Date |

|

Start construction |

2 January 2019 |

|

Commissioning

of new infrastructure facilities |

2020 |

|

Demolition of

existing infrastructure facilities |

2021 |

|

Start waste

intake at SENTX |

21 November 2021 |

|

Estimated

exhaustion date of. SENTX |

2027 |

|

End of

aftercare for SENTX |

2059 |

The major construction works of the SENTX includes:

• Site

formation at the TKO Area 137 and the existing infrastructure area at SENT Landfill;

• Construction

of surface and groundwater drainage systems;

• Construction

of the leachate containment and collection systems;

• Construction

of new leachate and landfill gas treatment facilities, site offices,

maintenance yards at the new infrastructure area;

• Construction

of new pipelines to transfer the leachate and landfill gas collected from the

existing SENT Landfill to the treatment facilities at the new infrastructure area;

• Construction

of the site access and new waste reception facilities; and

• Demolition

of the facilities at the existing SENT Landfill infrastructure area.

This is the Monthly EM&A Report for the Project which summarises the key findings of the EM&A programme during the reporting period from 1 to 31 August

2024 for the construction and operation works.

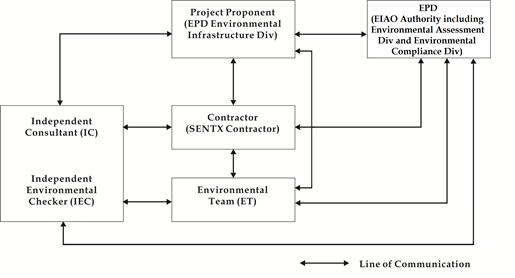

The organisation structure of

the Project is presented in Figure 1.2.

Figure 1.2 Organisation Chart

Contact details of the key personnel are summarised in Table 1.2 below.

Table 1.2

Contact Information of Key Personnel

|

Party |

Position |

Name |

Telephone |

|

Contractor (Green Valley Landfill Limited) |

Project Manager |

Carl Lai |

2706 8829 |

|

Environmental

Team (ET) (ERM-Hong Kong,

Limited) |

ET Leader |

Terence Fong |

2271 3156 |

|

Independent

Environmental Checker (IEC) (Meinhardt Infrastructure and Environment

Limited) |

IEC |

Claudine Lee |

2859 5409 |

The programme of the

construction is shown in Annex

A. As informed by the Contractor, the major works carried out in this

reporting period include:

• Maintenance

and improvement of temporary surface water drainage; and

• Restoration

of Phase 1 Cell 1X, 2X and Phase 2 Cell 3X west slopes.

The implementation schedule of the mitigation measured

recommended in the Updated EM&A Manual is presented in Annex B.

The status for all environmental aspects are

presented in Table 1.3. The EM&A requirements remained

unchanged during the reporting period.

Table 1.3 Summary of Status

for the Environmental Aspects under the Updated EM&A Manual

|

Parameters |

Status |

|

Air Quality |

|

|

Baseline

Monitoring |

The results of

baseline air quality monitoring were reported in Baseline Monitoring Report

and Pre-operation Baseline Monitoring Report and submitted to EPD under EP

Condition 3.3 |

|

Impact

Monitoring |

On-going |

|

Noise |

|

|

Baseline

Monitoring |

The results of baseline

noise monitoring were reported in Baseline Monitoring Report and submitted to

EPD under EP Condition 3.3 |

|

Impact

Monitoring |

On-going |

|

Water

Quality |

|

|

Baseline

Monitoring |

The results of

baseline surface water quality monitoring were reported in Baseline

Monitoring Report and Pre-operation Baseline Monitoring Report and submitted

to EPD under EP Condition 3.3 |

|

Impact

Monitoring |

On-going |

|

Landfill Gas |

|

|

Impact

Monitoring |

On-going |

|

Waste Management |

|

|

Waste

Monitoring |

On-going |

|

Landscape and Visual |

|

|

Baseline

Monitoring |

The results of

baseline landscape and visual monitoring were reported in Baseline Monitoring

Report and submitted to EPD under EP Condition 3.3 |

|

Operation

Phase Audit |

On-going |

|

Site

Environmental Audit |

|

|

Regular Site

Inspection |

On-going |

|

Complaint

Hotline and Email Channel |

On-going |

|

Environmental

Log Book |

On-going |

Taking into

account the operation works, impact monitoring of air quality, noise,

water quality, landfill gas and waste management were carried out in the

reporting period. The impact monitoring schedule of air quality, noise, water

quality and landfill gas monitoring are provided in Annex C.

The EM&A programme also

involved environmental site inspections and related auditing conducted by the

ET for checking the implementation of the required environmental mitigation

measures recommended in the approved EIA Report and relevant EP submissions. To

promote the environmental awareness and enhance the environmental performance

of the contractors, environmental trainings and regular environmental

management meetings were conducted during the reporting period, which are

summarized as below:

·

One environmental management meeting was held

with the Contractor, ET, IEC and EPD on 15 August 2024; and

·

Environmental toolbox trainings on Coverage of

Regulated Electrical Equipment (REE) Expanded and Mosquito Nuisance were

provided on 8 August 2024 and 22 August 2024, respectively by the Contractor to

the workers.

The status of statutory environmental compliance with the EP

conditions under the EIAO, submission status under the EP and implementation

status of mitigation measures are presented in Table 1.4.

Table 1.4 Status of

Submissions required under the EP and Implementation Status of Mitigation

Measures

|

EP Condition |

Submission / Implementation Status |

Status |

|

2.3 |

Management Organisation of Main Construction Companies |

Submitted and

accepted by EPD. |

|

2.4 |

Setting up of

Community Liaison Group |

Community

Liaison Group was set up. |

|

2.5 |

Submission of

Detailed Landfill Gas Hazard Assessment Report |

Submitted and

accepted by EPD on 10 January 2019. |

|

2.6 |

Submission of

Restoration and Ecological Enhancement Plan |

Submitted to

EPD on 28 June 2019. |

|

2.7 |

Setting up of

Trial Nursery |

Trial Nursery

works was commenced on 28 August 2019. |

|

2.8 |

Advance Screen

Planting |

Advance Screen

Planting works were completed on 28 June 2019. |

|

2.9 |

Provision of

Multi-layer Composite Liner System |

Under

implementation. |

The environmental licenses and permits (including EP, Water

Pollution Control Ordinance (WPCO) discharge license, registration as a

chemical waste producer, and construction noise permit) that are valid in the

reporting period are presented in Table 1.5. No non-compliance with

environmental statutory requirements was identified.

Table 1.5 Status of

Statutory Environmental Requirements

|

Description |

Ref No. |

Status |

|

Environmental Permit |

EP-308/2008 |

Granted on 5

August 2008 |

|

Variation of

Environmental Permit |

EP-308/2008/A |

Granted on 6

January 2012 |

|

EP-308/2008/B |

Granted on 20

January 2017 |

|

|

EP-308/2008/C |

Granted on 29

February 2024 |

|

|

Further

Environmental Permit |

FEP-01/308/2008/B |

Granted on 16

May 2018 |

|

FEP-01/308/2008/C |

Granted on 29

February 2024 |

|

|

Water Discharge

License under WPCO (Permit Holder: GVL) |

Licence No.: WT00041447-2022 (a) |

Validity from 17 June 2022 to 30 June 2024 (a) |

|

Licence No.: WT10003277-2024 (a)

|

Validity from 23 August 2024 to 30 June 2026 (a) |

|

|

Billing

Account for Disposal of Construction Waste |

Chit Account

Number: 5001692 |

Approved on 28

December 2005 |

|

Registration

as a Chemical Waste Producer (Permit Holder: GVL) |

5296-839-G2228-01 |

Issued on 31

December 2015 |

|

Construction

Noise Permit (Permit Holder: GVL) |

GW-RE0307-24 |

Validity from

22 March 2024 to 14 September 2024 |

|

(a) The renewal of WPCO Discharge License was in

progress between 1 July 2024 and 22 August 2024. As per EPD’s

confirmation, GVL is still permitted to conduct business complying with the

equipment of expired WPCO license (WT00041447-2022) as the renewal was under processing by EPD. |

||

The EM&A programme for the

Project required environmental monitoring for air quality, noise, water quality

and landfill gas as well as environmental site inspections for air quality,

noise, water quality, landfill gas, waste management, and landscape and visual

impacts. The EM&A requirements and related findings for each component are summarised in the following sections.

According to the updated EM&A Manual of the Project,

impact dust monitoring (in term of Total Suspended Particulates (TSP)) was

carried out at the four designated locations along the site boundary (i.e. AM1,

AM2, AM3 and AM4) during the operation/restoration phase, at a 6-day interval.

The Action and Limit Levels of the dust monitoring is

provided in Table 2.1 below.

Table 2.1 Action and Limit

Levels for 24-hour TSP

|

Monitoring Station |

Action Level |

Limit Level |

|

AM1 - SENTX Site Boundary (North) |

•

260 µg m-³ |

•

260 µg m-³ |

|

AM2 - SENTX Site Boundary (West, near DP3) |

||

|

AM3 - SENTX

Site Boundary (West, near RC15) |

||

|

AM4 - SENTX

Site Boundary (West, near EPD building) |

High volume air samplers (HVSs) in compliance with the

specifications listed under Section 3.2.2 of the updated EM&A Manual were

used to measure 24-hour TSP levels at the dust monitoring stations. The HVSs

were calibrated upon installation and thereafter at bi-monthly intervals to

check the validity and accuracy of the results.

The equipment used in the impact dust monitoring programme and monitoring locations are summarised

in Table 2.2 and illustrated in Figure 2.1, respectively. Copies of the

calibration certificates for the equipment are presented in Annex D1.

Table 2.2 Dust Monitoring

Details

|

Monitoring Station |

Location |

Parameter |

Frequency and Duration |

Monitoring Dates |

Equipment |

|

AM1 |

SENTX Site Boundary (North) |

•

24-hour TSP |

•

Once every 6 days |

•

5, 11, 17, 23, 29 Aug 2024 |

• Tisch

TE-5170 (S/N: 3976) |

|

AM2 |

SENTX Site Boundary (West, near DP3) |

•

Tisch TE-5170 (S/N: 3573) |

|||

|

AM3 |

SENTX Site

Boundary (West, near RC15) |

•

Tisch TE-5170 (S/N: 3572) |

|||

|

AM4 |

SENTX Site

Boundary (West, near EPD building) |

·

Tisch TE-5170 (S/N: 3957) |

The schedule for dust monitoring during the reporting period

is provided in Annex C.

The monitoring results for 24-hour TSP are summarised in Table 2.3. The detailed monitoring

results and the graphical presentation of the 24-hour TSP results at each

monitoring location are provided in Annex D2.

Table 2.3 Summary of 24-hour

TSP Monitoring Results in the Reporting Period

|

Monitoring Station Location |

Average 24-hr TSP

Concentration (µg m-3) (Range in bracket) |

Action Level (µg/m3) |

Limit Level (µg/m3) |

|

AM1 - SENTX Site Boundary (North) |

75 (23 – 107) |

260 |

260 |

|

AM2 - SENTX Site Boundary (West, near DP3) |

85 (27 – 151) |

260 |

260 |

|

AM3 - SENTX

Site Boundary (West, near RC15) |

114 (30 – 225) |

260 |

260 |

|

AM4 - SENTX

Site Boundary (West, near EPD building) |

55 (20 – 74) |

260 |

260 |

The major dust sources in the

reporting period included fugitive dust emission from exposed area in SENTX as

well as nearby operations of the TKO Area 137 Fill Bank.

No Action and Limit Levels exceedance was recorded for TSP

monitoring in the reporting period. No action is thus required to be

undertaken in accordance with the Event and Action Plan presented in Annex D3.

Meteorological data obtained from the SENTX on-site

meteorological monitoring station was used for the dust monitoring and is shown

in Annex D4. It is

considered that meteorological data obtained at the on-site meteorological

monitoring station is representative of the Project area and could be used for

the operation/restoration phase dust monitoring programme

for the Project.

According to the updated EM&A Manual of the Project, odour patrol was carried out along the site boundary during

the operation/ restoration phase.

During the first month of operation, daily odour patrol (3 times per day) was conducted jointly by the

ET and the IEC. The odour intensity detected was

based on that determined by the IEC. In addition, an independent party (ALS Technichem (HK) Pty Ltd.) was appointed to undertake odour patrol together with the ET and IEC three times per

week. During these patrols, the odour intensity

detected was based on that determined by the independent third party.

Reduction of odour monitoring

frequency from Period 1 (daily, three times per day) to Period 2 (weekly) was

approved by EPD on 4 February 2022. Weekly odour

patrol was conducted jointly by the ET and the IEC from 10 February 2022.

In addition, an independent party (ALS Technichem

(HK) Pty Ltd.) was appointed to undertake odour

patrol together with the ET and IEC once every two weeks.

Reduction of odour monitoring

frequency from Period 2 (weekly) to Period 3 (monthly) was approved by EPD on 2

June 2022. Monthly odour patrol was conducted

jointly by the ET and the IEC from 28 June 2022. In addition, an

independent party (ALS Technichem (HK) Pty Ltd.) was

appointed to undertake odour patrol together with the

ET and IEC quarterly. Furthermore, the odour patrol

route has been reviewed against the latest construction / operation programme and approved by EPD on 17 June 2024.

The Action and Limit Levels for odour

patrol is provided in Table 2.4 below.

Table 2.4 Action and Limit

Levels for Odour Patrol

|

Parameter |

Action Level |

Limit Level |

|

Perceived odour intensity

and odour complaints |

· Odour

intensity ≥ Class 2 recorded; or · One

documented complaint received |

· Odour

intensity ≥ Class 3 recorded on 2 consecutive patrol

(a) (b) |

|

Notes: (a) i.e. either Class 3-strong or

Class 4-extreme odour intensity. (b) The exceedances of the odour

intensity do not need to be recorded at the same location. |

||

Odour patrol

was conducted by trained personnel/competent persons with a specific

sensitivity to a reference odour (i.e. on reference

materials n-butanol with the concentration of 50ppm in nitrogen (v/v)) in

compliance with Section 3.7.2 of the updated EM&A Manual patrolling and

sniffing along the SENTX Site boundary to detect any odour.

The odour monitoring programme and patrol route are summarised

in Table 2.5 and illustrated in Figure 2.2 respectively. Copies of the

certificates of the qualified odour panelist are

presented in Annex D5.

Table 2.5 Odour Monitoring

Details

|

Patrol Locations |

Parameters |

Patrol Frequency (a) |

Monitoring Dates |

|

Patrol along the SENTX Site Boundary (Checkpoints OP1

– OP17) |

Odour Intensity (see Table

2.6) |

Period 1 - First month of operation Daily, three

times a day in the morning, afternoon and evening/night (between 18:00 and

22:00 hrs) conducted by the ET and the IEC Three times

per week on different days conducted by an independent third party together

with the ET and IEC (b) Period 2 - Three months following period 1 (c) Weekly

conducted by the ET and the IEC Once every two weeks conducted by

an independent third party together with the ET and IEC (b) Period 3 - Throughout operation following period 2 (c) Monthly

conducted by the ET and the IEC Quarterly conducted by an independent third party

together with the ET and IEC (b) |

Conducted by

ET & IEC: 1 Aug 2024 Conducted by

an independent third party, ET & IEC: - |

|

Notes: (a) Reduction of monitoring

frequency will be subject to the monitoring results to demonstrate

environmentally acceptable performance. (b) Patrol shall be scheduled so

that they are carried out together with the patrols to be carried out jointly

by the ET and the IEC. (c) Commencement

of each period will be

justified by the ET Leader and verified by the IEC and will be subject to

agreement with the EPD (EIAO Authority) and Project Proponent. |

|||

Table 2.6 Odour Intensity

Level

|

Class |

Odour Intensity |

Description |

|

0 |

Not

Detected |

No odour perceived or an odour so weak that it cannot be easily characterised or described. |

|

1 |

Slight

|

Identified odour, slight |

|

2 |

Moderate |

Identified odour, moderate |

|

3 |

Strong

|

Identified odour, strong |

|

4 |

Extreme

|

Severe odour |

The schedule for odour patrol

during the reporting period is provided in Annex C.

The odour monitoring results are summarised and provided in Table 2.7 and Annex D6, respectively.

Table 2.7 Summary of Odour

Monitoring Results in the Reporting Period

|

Odour Checkpoints |

Odour Intensity Class |

Action Level |

Limit Level |

|

OP1 |

0 |

Odour intensity ≥

Class 2 recorded |

Odour intensity ≥

Class 3 recorded on 2 consecutive patrol |

|

OP2 |

0 |

||

|

OP3 |

0 |

||

|

OP4 |

0 |

||

|

OP5 |

0 |

||

|

OP6 |

0 |

||

|

OP7 |

0 |

||

|

OP8 |

0 |

||

|

OP9 |

0 |

||

|

OP10 |

0 |

||

|

OP11 |

0 |

||

|

OP12 |

1 |

||

|

OP13 |

0 |

||

|

OP14 |

0 |

||

|

OP15 |

N/A (a) |

||

|

OP16 |

N/A (a) |

||

|

OP17 |

N/A (a) |

||

|

Note: (a) OP15 – OP17 are not accessible due to safety

considerations (after heavy rainstorm). |

|||

The potential odour

source in the reporting period included the Cell 4X tipping area at SENTX. All

the odour monitoring results were below the Action

and Limit Levels in the reporting period. No action is thus required to be

undertaken in accordance with the Event and Action Plan presented in Annex D3.

According to the updated EM&A Manual of the Project, the

performance of the thermal oxidiser, landfill gas

flare and landfill gas generator was monitored when they are in operation. Gas

samples were collected from the stack of the thermal oxidizer, landfill gas

flare and landfill gas generator for laboratory analysis for NO2,

CO, SO2, Benzene and Vinyl chloride and in-situ analysis for

exhaust gas velocity at monthly interval and for laboratory analysis for

non-methane organic compounds and ammonia (for thermal oxidizer only) at

quarterly interval. The operating conditions

of the thermal oxidiser, landfill gas flare and

landfill gas generator were also monitored continuously.

The Limit Levels for stack emission of the thermal oxidiser, landfill gas flare and landfill gas generator are

provided in Tables 2.8 – 2.10 below.

Table 2.8 Limit Levels for

Stack Emission of the Thermal Oxidiser

|

Parameters |

Limit Level |

|

NO2 |

1.58 gs-1 |

|

CO |

0.53 gs-1 |

|

SO2 |

0.07 gs-1 |

|

Benzene |

3.01 x 10-2 gs-1 |

|

Vinyl

chloride |

2.23 x 10-3 gs-1 |

|

Gas

combustion temperature |

850oC (minimum) |

|

Exhaust

gas exit temperature |

443K (minimum) (a) |

|

Exhaust

gas velocity |

7.5 ms-1 (minimum) (a) |

|

Note: (a) Level

under full load condition. |

|

Table 2.9 Limit Levels for

Stack Emission of the Landfill Gas Flare

|

Parameters |

Limit Level |

|

NO2 |

0.97 gs-1 |

|

CO |

2.43 gs-1 |

|

SO2 |

0.22 gs-1 |

|

Benzene |

4.14 x 10-4 gs-1 |

|

Vinyl

chloride |

2.60 x 10-4 gs-1 |

|

Gas

combustion temperature |

815oC (minimum) |

|

Exhaust

gas exit temperature |

923 K (minimum) (a) |

|

Exhaust

gas velocity |

9.0 m s-1 (minimum) (a) |

|

Note: (a) Level

under full load condition. |

|

Table 2.10 Limit Levels for Stack Emission of the Landfill

Gas Generator

|

Parameters |

Limit Level |

|

NO2 |

1.91 gs-1 |

|

CO |

2.48 gs-1 |

|

SO2 |

0.528 gs-1 |

|

Benzene |

2.47 x 10-4 gs-1 |

|

Vinyl

chloride |

1.88 x 10-5 gs-1 |

|

Gas

combustion temperature |

450oC (minimum) |

|

Exhaust

gas exit temperature |

723K (minimum) (a) |

|

Exhaust

gas velocity |

30.0 ms-1 (minimum) (a) |

|

Note: (a) Level

under full load condition. |

|

Gas samples were collected from the

centroid of the stack with stainless steel sampling probe, into inert sample

containers (i.e. Canister and Tedlar Bag) and

transferred to ALS Technichem (HK) Pty Ltd. (HOKLAS

Registration No. 066) laboratory within 24 hours of collection for direct

analysis on a gas chromatography within 48 hours after collection. The

flue gas velocity of the gas stream at the exhaust of thermal oxidize was

determined by S-Pitot tube during the emission sampling.

The stack emission monitoring programme

and monitoring locations are summarised in Table

2.11 and illustrated in Figure 2.1, respectively.

Table 2.11 Thermal Oxidiser, Landfill Gas Flare and

Landfill Gas Generator Stack Emission Monitoring Details

|

Monitoring Location |

Parameter |

Frequency |

Monitoring Date |

|

Stack

of Thermal Oxidiser |

Laboratory

analysis for · NO2 · CO · SO2 · Benzene · Vinyl

chloride In-situ analysis for · Exhaust gas velocity |

Monthly for the first 12 months of operation and

thereafter at quarterly intervals |

21 Aug 2024 |

|

Laboratory

analysis for · Non-methane organic compounds

CO |

Quarterly for the 1st year of operation (b) |

21 Aug 2024 |

|

|

Laboratory

analysis for · Ammonia · Gas

combustion temperature · Exhaust

temperature · Exhaust

gas velocity (a) |

Quarterly |

21 Aug 2024 |

|

|

· Gas

combustion temperature · Exhaust

temperature · Exhaust gas

velocity (a) |

Continuously |

1 – 31 Aug 2024 |

|

|

Stack

of Landfill Gas Flare |

Laboratory

analysis for · NO2 · CO · SO2 · Benzene · Vinyl

chloride In-situ analysis for · Exhaust gas velocity |

Monthly for the first 12 months of operation and

thereafter at quarterly intervals |

20 Aug 2024 |

|

Laboratory

analysis for · Non-methane organic compounds

CO |

Quarterly for the 1st

year of operation (b) |

20 Aug 2024 |

|

Monitoring Location |

Parameter |

Frequency |

Monitoring Date |

|

Stack

of Landfill Gas Flare |

· Gas

combustion temperature · Exhaust

temperature · Exhaust

gas velocity (a) |

Continuously |

1 – 31 Aug 2024 |

|

Stack

of Landfill Gas Generator |

Laboratory

analysis for · NO2 · CO · SO2 · Benzene · Vinyl

chloride In-situ analysis for · Exhaust gas velocity |

Monthly for the first 12 months of operation and

thereafter at quarterly intervals |

20 Aug 2024 |

|

Laboratory

analysis for · Non-methane organic compounds |

Quarterly for the 1st year of operation (b) |

20 Aug 2024 |

|

|

· Exhaust

temperature · Exhaust gas

velocity (a) |

Continuously |

1 – 31 Aug 2024 |

|

|

Notes: (a) The

exhaust gas velocity is calculated based on the cross-section area of the

stack and continuous monitored gas flow and combustion temperature data. (b) The monitoring results are

being reviewed to determine if monitoring of this parameter can be terminated

upon agreement by the EIAO Authority, IEC and Project Proponent. |

|||

The schedule for thermal oxidizer, landfill gas flare and landfill

gas generator stack emission monitoring during the reporting period is provided

in Annex C.

The thermal oxidizer, landfill gas flare and landfill gas

generator stack emission monitoring results and detailed continuous monitoring

results are summarised in Tables 2.12 - 2.14

and provided in Annex D7,

respectively.

Table 2.12 Summary of Thermal Oxidiser Stack Emission

Monitoring in the Reporting Period

|

Parameters |

Monitoring Results (Range

in Bracket) |

Limit Level |

|

NO2 |

0.57 gs-1 |

1.58 gs-1 |

|

CO |

0.03 gs-1 |

0.53 gs-1 |

|

SO2 |

<0.01 gs-1 |

0.07 gs-1 |

|

Benzene |

<2.0 x 10-4 gs-1 |

3.01 x 10-2 gs-1 |

|

Vinyl

chloride |

<1.3 x 10-4 gs-1 |

2.23 x 10-3 gs-1 |

|

Non-Methane

Organic Carbons |

<0.003 gs-1 |

- |

|

Ammonia |

0.0315 gs-1 |

- (c) |

|

Gas

combustion temperature |

900oC (895oC – 904oC) |

850oC (minimum) |

|

Exhaust

gas exit temperature |

1,206K (1,200K – 1,214K) |

443K (minimum) (a) |

|

Exhaust

gas velocity |

9.4 ms-1 (b) |

7.5 ms-1 (minimum) (a) |

|

Notes: (a) Level under full load condition. (b) The exhaust gas velocity was

calculated based on the cross-section area of the stack and the gas flow and

combustion temperature data measured during the stack emission monitoring. (c) The

emission limit for ammonia is under review and will be supplemented in

subsequent revision. |

||

Table 2.13 Summary of Landfill Gas Flare Stack Emission

Monitoring in the Reporting Period

|

Parameters |

Monitoring Results

(Range in Bracket) |

Limit Level |

|

NO2 |

<0.02 gs-1 |

0.97 gs-1 |

|

CO |

0.02 gs-1 |

2.43 gs-1 |

|

SO2 |

0.01 gs-1 |

0.22 gs-1 |

|

Benzene |

<1.17 x 10-4 gs-1 |

4.14 x 10-4 gs-1 |

|

Vinyl

chloride |

<9.4 x 10-5 gs-1 |

2.60 x 10-4 gs-1 |

|

Non-Methane

Organic Carbons |

<0.002 gs-1 |

- |

|

Gas

combustion temperature |

Flare 1: 866oC

(840oC – 890oC) Flare 2: 896oC (865oC – 928oC) |

815oC (minimum) |

|

Exhaust gas

exit temperature |

Flare 1: 1,124K (1,096K – 1,151K) Flare 2:

1,154K (1,126K – 1,190K) |

923 K (minimum) (a) |

|

Exhaust gas

velocity |

9.0 ms-1 (b) |

9.0 m s-1 (minimum) (a) |

|

Notes: (a) Level under full load condition. (b) The exhaust gas velocity was

calculated based on the cross-section area of the stack and the gas flow and

combustion temperature data measured during the stack emission monitoring. |

||

Table 2.14 Summary of Landfill Gas Generator Stack Emission

Monitoring in the Reporting Period

|

Parameters |

Monitoring Results (Range

in Bracket) |

Limit Level |

|

NO2 |

0.018 gs-1 |

1.91 gs-1 |

|

CO |

0.715 gs-1 |

2.48 gs-1 |

|

SO2 |

0.002 gs-1 |

0.528 gs-1 |

|

Benzene |

3.7 x 10-5 gs-1 |

2.47 x 10-4 gs-1 |

|

Vinyl

chloride |

<8.9 x 10-6 gs-1 |

1.88 x 10-5 gs-1 |

|

Non-Methane

Organic Carbons |

0.0023 gs-1 |

- |

|

Exhaust

gas exit temperature |

ENGA: 868K (844K – 886K) ENGB: 866K

(837K – 875K) |

723K (minimum) (a) |

|

Exhaust

gas velocity |

8.8 ms-1 (b) |

30.0 ms-1 (minimum) (a) |

|

Notes: (a) Level under full load condition. (b) The exhaust gas velocity was

calculated based on the cross-section area of the stack and the gas flow and

combustion temperature data measured during the stack emission monitoring. |

||

No Action

and Limit Level exceedance was recorded for thermal oxidizer, landfill gas

flare and landfill gas generator stack emission monitoring in the reporting

period. No action is thus required to be undertaken in accordance with the

Event and Action Plan presented in Annex D3.

According to the updated EM&A Manual of the Project,

ambient VOCs, ammonia and H2S monitoring was carried out at the four

designated locations along the site boundary (i.e. AM1, AM2, AM3 and AM4)

during the operation/restoration phase, at quarterly interval.

The Limit Levels for ambient VOCs, ammonia and H2S

monitoring is provided in Table 2.15 below.

Table 2.15 limit levels for ambient vocs, ammonia and h2s

monitoirng

|

Parameters |

Limit Level (µg m-³) |

|

Methane

|

NA (a) |

|

Ammonia

|

180 |

|

H2S |

42 |

|

Dichlorodifluoro-methane |

NA (a) |

|

Vinyl

Chloride |

26 |

|

Methanol |

2,660 |

|

Ethanol |

19,200 |

|

Dimethylsulphide |

8 |

|

Carbon

Disulphide |

150 |

|

Methylene

Chloride |

3,530 |

|

Chloroform |

99 |

|

Methyl

propionate |

353 |

|

Butan-2-ol |

667 |

|

1.1.1-Trichloroethane |

5,550 |

|

1.2-Dichloroethane |

210 |

|

Benzene |

33 |

|

Carbon

Tetrachloride |

64 |

|

Dipropyl

ether |

NA (a) |

|

Heptane |

2,746 |

|

Trichloroethylene |

5,500 |

|

Ethyl

propionate |

29 |

|

Methyl

butanoate |

30 |

|

Methanethiol |

10 |

|

Toluene |

1,244 |

|

Ethyl

butanoate |

71 |

|

Propyl

benzene |

19 |

|

Octane |

7,942 |

|

Propyl

propionate |

276 |

|

1.2-Dibromoethane

(EDB) |

39 |

|

Butyl

acetate |

7,240 |

|

Tetrachloroethylene |

1,380 |

|

Ethyl

benzene |

738 |

|

Nonane |

11,540 |

|

Ethanethiol |

13 |

|

Decanes |

3,608 |

|

Limonene |

212 |

|

Butyl

benzene |

47 |

|

Undecane |

5,562 |

|

Butanethiol |

4 |

|

Terpenes |

NA (a) |

|

Xylenes |

534 |

|

Dichlorobenzene |

120 |

|

Note: (a) No relevant

WHO/USEPA/CARB’s ambient criteria, odour thresholds

and WEL available. |

|

Ambient air samples were drawn into the pre-cleaned and

vacuum canister directly when the valve of the flow controller (with preset

flow rate) was opened. After sampling, the valve will be closed manually

and the canister with VOCs gas samples were transported for laboratory

analysis.

Pre-cleaned Tedlar bag was placed

in the vacuum chamber. Ambient air was collected in the Tedlar bag under the vacuum condition when the pump is

switched on. The Tedlar bag was filled up to

90% of total capacity to avoid leakage and bag deformation. After

sampling, pump is switched off and the valve of Tedlar

bag was closed manually. The air samples were transported back to

laboratory for analysis.

Calibrated personal air pump was used to pump the air

through a sulfuric acid-treated silica gel sorbent tube. Gaseous ammonia

in air was then trapped in the sorbent tube. The tube was transported

back to laboratory for analysis.

H2S in air is collected in mid-get impingers by

aspirating a measured volume of air through an alkaline suspension

of cadmium hydroxide (as the absorbing solution). The sulphide

is precipitated as cadmium sulphide to prevent air

oxidation of the sulphide. Arabinogalactan is

added to the cadmium hydroxide slurry prior to sampling to minimize photo-decomposition of the precipitated cadmium sulphide. The solution is transported back to

laboratory for analysis.

All air samples collected for laboratory analysis were

transported to ALS Technichem (HK) Pty Ltd. (HOKLAS

Registration No. 066) laboratory within 24 hours and analysed

within 48 hours.

The ambient VOCs, ammonia and H2S monitoring programme and monitoring locations are summarised

in Table 2.16 and illustrated in Figure 2.1, respectively.

Table 2.16 ambient vocs, ammonia and h2s monitoirng details

|

Monitoring Station |

Location |

Parameter |

Frequency |

Monitoring Date |

|

AM1 |

SENTX Site Boundary (North) |

·

Methane ·

Ammonia ·

A suite of VOCs (a) ·

H2S |

Quarterly |

22 Aug 2024 |

|

AM2 |

SENTX Site Boundary (West, near DP3) |

|||

|

AM3 |

SENTX Site Boundary (West, near RC15) |

|||

|

AM4 |

SENTX Site Boundary (West, near EPD building) |

|||

|

Note: (a) A suite of VOCs includes: |

||||

|

·

Butyl benzene ·

Xylenes ·

Decanes ·

Undecane ·

Limonene ·

Terpenes ·

Ethanol ·

Butan-2-ol ·

Dimethylsulphide ·

Methyl propionate ·

Ethyl propionate ·

Propyl propionate ·

Butyl acetate

|

·

Dichlorobenzene ·

Methyl butanoate ·

Dipropyl ether ·

Methanethiol ·

Ethanethiol ·

Butanethiol ·

Methanol ·

Heptanes ·

Octanes ·

Nonanes ·

Dichlorodifluoro-methane

|

||

The schedule for ambient VOCs, ammonia and H2S

monitoring during the reporting period is provided in Annex C.

The ambient VOCs, ammonia and H2S monitoring

results are summarized in Tables 2.17 and provided in Annex D8.

Table 2.17 summary of ambient vocs, ammonia and h2s

monitoring results in the reporting period

|

Parameters |

Limit Level (µg m-³) |

Monitoring Results (µg m-³) |

|||

|

AM1 |

AM2 |

AM3 |

AM4 |

||

|

Ammonia

|

180 |

<10 |

<10 |

<10 |

<10 |

|

H2S |

42 |

<15 |

<15 |

<15 |

<15 |

|

Methane

|

NA (a) |

0.00018 %(v/v) |

0.00018

%(v/v) |

0.00018 %(v/v) |

0.00018 %(v/v) |

|

1.1.1-Trichloroethane |

5,550 |

<0.8 |

<0.8 |

<0.8 |

<0.8 |

|

1.2-Dibromoethane

(EDB) |

39 |

<1.0 |

<1.0 |

<1.0 |

<1.0 |

|

1.2-Dichloroethane |

210 |

<0.3 |

<0.3 |

<0.3 |

<0.3 |

|

Benzene |

33 |

1.2 |

<0.5 |

<0.5 |

<0.5 |

|

Butan-2-ol |

667 |

<0.6 |

<0.6 |

<0.6 |

<0.6 |

|

Butanethiol |

4 |

<1.2 |

<1.2 |

<1.2 |

<1.2 |

|

Carbon

Disulphide |

150 |

0.5 |

0.7 |

1 |

0.5 |

|

Carbon

Tetrachloride |

64 |

<0.6 |

0.6 |

0.6 |

0.6 |

|

Chloroform |

99 |

<0.8 |

<0.8 |

<0.8 |

<0.8 |

|

Decanes |

3,608 |

<0.7 |

<0.7 |

<0.7 |

<0.7 |

|

Dichlorobenzene |

120 |

<1.0 |

<1.0 |

<1.0 |

<1.0 |

|

Dichlorodifluoro-methane |

NA (a) |

1.5 |

1.8 |

1.9 |

1.7 |

|

Dimethylsulphide |

8 |

<0.2 |

<0.2 |

<0.2 |

<0.2 |

|

Dipropyl

ether |

NA (a) |

<0.8 |

<0.8 |

<0.8 |

<0.8 |

|

Limonene |

212 |

0.6 |

0.5 |

0.6 |

0.5 |

|

Ethanethiol |

13 |

<0.6 |

<0.6 |

<0.6 |

<0.6 |

|

Ethanol |

19,200 |

<3.8 |

<3.8 |

4.1 |

10.7 |

|

Ethyl

butanoate |

71 |

<1.0 |

<1.0 |

<1.0 |

<1.0 |

|

Ethyl

propionate |

29 |

<0.8 |

<0.8 |

<0.8 |

<0.8 |

|

Ethyl

benzene |

738 |

<0.5 |

<0.5 |

<0.5 |

<0.5 |

|

Heptane |

2,746 |

<0.8 |

<0.8 |

<0.8 |

1.5 |

|

Methanethiol |

10 |

<0.4 |

<0.4 |

<0.4 |

<0.4 |

|

Methanol |

2,660 |

17.5 |

19.2 |

34.7 |

35.1 |

|

Methyl

butanoate |

30 |

<0.8 |

<0.8 |

<0.8 |

<0.8 |

|

Methyl

propionate |

353 |

<0.7 |

<0.7 |

<0.7 |

<0.7 |

|

Methylene

Chloride |

3,530 |

1.2 |

1.8 |

1 |

0.7 |

|

Butyl

acetate |

76 |

<1.0 |

<1.0 |

<1.0 |

<1.0 |

|

Butyl

benzene |

47 |

<1.0 |

<1.0 |

<1.0 |

<1.0 |

|

Nonane |

11,540 |

<0.9 |

<0.9 |

<0.9 |

<0.9 |

|

Propyl

benzene |

19 |

<0.8 |

<0.8 |

<0.8 |

<0.8 |

|

Octane |

7,942 |

<0.9 |

<0.9 |

<0.9 |

<0.9 |

|

Propyl

propionate |

276 |

<1.0 |

<1.0 |

<1.0 |

<1.0 |

|

Terpenes |

NA (a) |

0.9 |

<0.8 |

1.2 |

<0.8 |

|

Tetrachloroethylene |

1,380 |

<0.7 |

<0.7 |

<0.7 |

<0.7 |

|

Toluene |

1,244 |

1 |

1.1 |

0.9 |

0.7 |

|

Trichloroethylene |

5,500 |

<1.1 |

<1.1 |

<1.1 |

<1.1 |

|

Undecane |

5,562 |

<1.2 |

<1.2 |

<1.2 |

<1.2 |

|

Vinyl

Chloride |

26 |

<0.3 |

<0.3 |

<0.3 |

<0.3 |

|

Xylenes |

534 |

1.1 |

1 |

0.8 |

0.8 |

|

Note: (a) No

relevant WHO/USEPA/CARB’s ambient criteria and WEL available. |

|||||

All ambient VOCs, ammonia and H2S

monitoring results were below the Limit Levels in the reporting period.

No action is thus required to be undertaken in accordance with the Event and

Action Plan presented in Annex

D3.

According to the updated EM&A Manual of the Project,

impact noise monitoring was conducted weekly at the monitoring location (i.e.

NM1) to obtain one set of 30-minute measurement between 07:00 and 19:00 hours

on normal weekdays.

The Action and Limit Levels for operational noise of the

Project are provided in Table 2.18 below.

Table 2.18 Action and Limit Levels for Operational Noise

|

Time Period |

Action Level (a) |

Limit Level (b) |

|

07:00 –

19:00 hrs on all days |

When one documented

complaint is received from any one of the noise sensitive receivers (NSRs) or 75 dB(A) recorded at the

monitoring station |

65 dB(A) at NSRs (c) |

|

19:00 –

23:00 hrs on all days |

65 dB(A) at NSRs (c) |

|

|

23:00 – 07:00 hrs on all days |

55 dB(A) at NSRs (c) |

|

|

Notes: (a) 75dB(A) along and at about 100m from

the SENTX site boundary was set as the Action Level. (b) Limits specified in the GW-TM and

IND-TM for construction and operational noise,

respectively. (c)

Limit Level

only apply to operational noise without road traffic and construction

activities noise. |

||

Noise monitoring was performed by

ALS Technichem (HK) Pty Ltd. (HOKLAS Registration No.

066) using sound level meter at the designated monitoring station NM1 (see Figure 2.1) in accordance

with the requirements stipulated in the updated

EM&A Manual. Acoustic calibrator was deployed to check the sound

level meter at a known sound pressure level. Details of the deployed equipment

are provided in Table 2.19. Copies of the calibration certificates for

the equipment are presented in Annex

E1.

Table 2.19 Noise Monitoring Details

|

Monitoring Station |

Location |

Parameter |

Frequency and Duration |

Monitoring Dates |

Equipment |

|

NM1 |

SENTX Site Boundary (North) |

Leq (30 min) measurement between 07:00 and 19:00

hours on normal weekdays (Monday to Saturday) |

Once per week for 30 mins during operation of the

Project |

6, 12, 19, 26 Aug 2024 |

Sound Level

Meter: Rion NL-52

(S/N: 01010406) Acoustic

Calibrator: CAL200

(S/N: 16878) |

The schedule for noise monitoring during the reporting

period is provided in Annex C.

A total of 4 impact noise monitoring events were scheduled

during the reporting period. Results for noise monitoring are summarised in Table 2.20. The

monitoring results and the graphical presentation of the data are provided in Annex E2.

Table 2.20 Summary of Operation Noise Monitoring Results in

the Reporting Period

|

|

Measured Noise Level Leq

(30 min), dB(A) |

||

|

Monitoring Station |

Average |

Range |

Action and Limit Level |

|

NM1 |

54.0 |

51.6 – 56.3 |

75 |

Major noise sources identified

during the noise monitoring included noise from operations of the SENTX and the

TKO Area 137 Fill Bank, aircrafts and insects.

No Action and Limit Levels exceedance was recorded for

operation noise monitoring in the reporting period. No action is thus

required to be undertaken in accordance with the Event and Action Plan

presented in Annex E3.

According to the updated EM&A Manual of the Project,

impact surface water quality monitoring was carried out at the three designated

surface water discharge points (i.e. DP3, DP4 and DP6) at monthly intervals

during operation/ restoration phase to ensure that the SENTX will not cause

adverse water quality impact.

The parameters as listed in Table 2.22 were

determined by ALS Technichem (HK) Pty Ltd. (HOKLAS

Registration No. 066).

The Limit Levels of the surface water quality impact

monitoring are provided in Table 2.21.

Table 2.21 Limit Levels for Surface Water Quality

|

Parameters |

Limit Level |

|

DP3 |

|

|

Ammoniacal-nitrogen |

> 0.5 mg/L |

|

COD |

> 80 mg/L |

|

SS |

> 30 mg/L |

|

DP4 & DP6 |

|

|

Ammoniacal-nitrogen |

> 7.1 mg/L |

|

COD |

> 30 mg/L |

|

SS |

> 20 mg/L |

|

Note: The limit levels specified for other parameters

in Table 10a of the Technical Memorandum Standards for Effluents Discharged

into Drainage and Sewerage Systems, Inland and Coastal Waters shall

also be followed. |

|

The locations of the monitoring

stations for the Project are shown in Figure 2.1. All in situ monitoring instruments

were checked, calibrated and certified by a laboratory accredited under HOKLAS

or other international accreditation scheme before use, and subsequently

re-calibrated at 3 monthly intervals throughout all stages of the surface water

quality monitoring programme. Calibration for a

DO meter was carried out before measurement according to the instruction manual

of the equipment model. Details of the equipment used in the impact surface

water quality monitoring works are provided in Table 2.22. Copies of the

calibration certificates for the equipment are presented in Annex F1.

Table 2.22 Impact Surface Water Quality Monitoring Details

|

Monitoring

Station |

Location |

Frequency |

Monitoring

Dates |

Parameter |

Equipment |

|

|

DP3 |

Surface water discharge

point DP3 |

Monthly |

7 Aug 2024 |

·

pH ·

Electrical conductivity (EC) ·

DO ·

SS ·

COD ·

BOD5 ·

TOC ·

Ammoniacal–nitrogen ·

Nitrate-nitrogen ·

Nitrite–nitrogen ·

TKN ·

TN ·

Phosphate ·

Sulphate ·

Sulphide ·

Carbonate ·

Oil & Grease |

·

Bicarbonate ·

Chloride ·

Sodium ·

Potassium ·

Calcium ·

Magnesium ·

Nickel ·

Manganese ·

Chromium ·

Cadmium ·

Copper ·

Lead ·

Iron ·

Zinc ·

Mercury ·

Boron |

Horiba U-52G (S/N:

NVAE08GT) |

|

DP4 |

Surface water discharge

point DP4 |

|||||

|

DP6 |

Surface water discharge

point DP6 |

|||||

The schedule for surface water quality monitoring during the

reporting period is provided in Annex

C.

One monitoring event for impact surface water quality

monitoring was scheduled at all designated monitoring stations during the

reporting period. However, sampling could not be carried out on 7 August 2024

due to insufficient flow. Details of impact water quality monitoring event are

provided in Annex F2.

No action is thus required to be undertaken in

accordance with the event and action plan presented in Annex F3.

According to the updated EM&A Manual, continuous

monitoring of leachate level and monthly monitoring of effluent quality were

carried out during the operation/ restoration phase.

Reduction of effluent monitoring frequency (dry season)

(from daily to monthly) was approved by EPD on 22 March 2022. Monthly

effluent quality monitoring (dry season) shall be conducted from 23 March

2022. The reduction of effluent monitoring frequency (wet season) (from

daily to monthly) was approved by EPD on 2 August 2022. Monthly effluent

quality monitoring (wet season) shall be conducted from 3 August 2022.

Temperature, pH and volume of the effluent discharged from the

leachate treatment plant were measured in-situ whereas the parameters as listed

in Table 2.24 were determined by ALS Technichem

(HK) Pty Ltd. (HOKLAS Registration No. 066).

The Limit Levels of the leachate monitoring are provided in Table

2.23.

Table 2.23 Limit Levels for Leachate Levels and Effluent

Quality

|

Parameters |

Limit Level |

|

Leachate Levels |

|

|

Leachate levels above the basal liner |

1 m above the primary liner of the leachate

containment system |

|

Effluent Quality |

|

|

Temperature |

> 43 °C |

|

pH Value |

6 – 10 |

|

Volume Discharged |

>2,000 m³ |

|

Suspended Solids (SS) |

> 800 mg/L |

|

Phosphate |

> 25 mg/L |

|

Sulphate |

> 800 mg/L |

|

Total Inorganic Nitrogen (a) |

> 100 mg/L |

|

Biochemical Oxygen Demand (BOD) |

> 800 mg/L |

|

Chemical Oxygen Demand (COD) |

> 2,000 mg/L |

|

Oil & Grease |

> 20 mg/L |

|

Boron |

> 7,000 µg/L |

|

Iron |

> 5 mg/L |

|

Cadmium |

> 1 µg/L |

|

Chromium |

> 300 µg/L |

|

Copper |

> 1,000 µg/L |

|

Nickel |

> 700 µg/L |

|

Zinc |

> 700 µg/L |

|

Note: (a)

Total

Inorganic Nitrogen include Ammoniacal-nitrogen, Nitrite-nitrogen and

Nitrate-nitrogen. |

|

All in situ monitoring

instruments were checked, calibrated and certified by a laboratory accredited under

HOKLAS or other international accreditation scheme before use, and subsequently

re-calibrated at 3 monthly intervals throughout all stages of the leachate

quality monitoring programme. Details of the

equipment used are provided in Table 2.24. Copies of the calibration

certificates for the equipment are presented in Annex F4.

Table 2.24 Leachate Levels and Effluent Quality Monitoring

Details

|

Location |

Frequency |

Parameter |

Monitoring Dates |

Equipment |

|

Leachate levels above the basal liner |

Continuous |

Leachate Levels |

1 – 31 Aug 2024 |

Pairs of pressure transducers |

|

Effluent discharged from LTP |

Daily for the first 3 months upon full operation of

the LTP at wet season (Apr to Sep) and dry season (Oct to Mar), respectively

and reduce to monthly thereafter subject to the monitoring results of the

first 3 months for each season and agreement with the EIAO Authority, IEC and

IC. (a) |

On-site Measurements: · Volume · pH · Temperature Laboratory analysis: · Suspended

Solids · COD · BOD5

· TOC · Ammoniacal–nitrogen

· Nitrate-nitrogen · Nitrite–nitrogen · Total

Nitrogen · Sulphate · Phosphate · Oil &

Grease · Alkalinity · Chloride · Calcium · Potassium · Magnesium · Iron · Zinc · Copper · Chromium · Nickel · Cadmium · Boron |

15 Aug 2024 |

TOA-DKK HM-30P (S/N:

790332) |

|

Note: (a)

Reduction of monitoring frequency will be subject to the monitoring

results to demonstrate environmentally acceptable performance. |

||||

The schedule for leachate monitoring during the reporting

period is provided in Annex C.

The leachate levels and effluent quality monitoring results

are summarised in Table 2.25 and Table 2.26,

respectively. The detailed monitoring results are provided in Annex F5 and Annex F6, respectively.

Table 2.25 Summary of Leachate Levels in the Reporting

Period

|

Monitoring Location |

Average Leachate Head

Levels (cm) (Range in Bracket) |

Limit Level (cm) |

|

Pump Station No. 1X (Cell 1X) |

||

|

Meter No. X-1 |

120 (102 – 144) |

>178 |

|

Meter No. X-2 |

112 (99 – 119) |

|

|

Average |

116 (104 – 132) |

|

|

Pump Station No. 2X (Cell 2X) |

||

|

Meter No. X-3 |

106 (106 – 106) |

>180 |

|

Meter No. X-4 |

119 (104 – 119) |

|

|

Average |

112 (105 – 113) |

|

|

Pump Station No. 3X (Cell 3X) |

||

|

Meter No. X-5 |

111 (99 – 119) |

> 175 |

|

Meter No. X-6 |

110 (99 – 119) |

|

|

Average |

111 (99 – 119) |

|

|

Pump Station No. 4X (Cell 4X) |

||

|

Meter No. X-7 |

114 (107 – 120) |

> 186 |

|

Meter No. X-8 |

113 (105 – 120) |

|

|

Average |

113 (106 – 120) |

|

Table 2.26 Summary of Effluent Quality Monitoring Results

in the Reporting Period

|

Parameters |

Monitoring Results |

Limit Level |

|

|

Effluent Discharged from LTP |

|

||

|

Temperature |

°C |

29.7 |

> 43 °C |

|

pH

Value |

pH unit |

8.5 |

6 – 10 |

|

Volume

Discharged |

m³ |

1,293 |

>2,000 m³ |

|

Suspended

Solids (SS) |

mg/L |

26.5 |

> 800 mg/L |

|

Phosphate |

mg/L |

7.2 |

> 25 mg/L |

|

Sulphate |

mg/L |

164 |

> 800 mg/L |

|

Total

Inorganic Nitrogen (a) |

mg/L |

36.54 |

> 100 mg/L |

|

BOD |

mg/L |

7 |

> 800 mg/L |

|

COD |

mg/L |

872 |

> 2,000 mg/L |

|

Oil

& Grease |

mg/L |

<5 |

> 20 mg/L |

|

Boron |

µg/L |

5120 |

> 7,000 µg/L |

|

Iron |

mg/L |

1.33 |

> 5 mg/L |

|

Cadmium |

µg/L |

<1.0 |

> 1 µg/L |

|

Chromium |

µg/L |

97 |

> 300 µg/L |

|

Copper |

µg/L |

<10 |

> 1,000 µg/L |

|

Nickel |

µg/L |

117 |

> 700 µg/L |

|

Zinc |

µg/L |

62 |

> 700 µg/L |

|

Note: (a) Total

Inorganic Nitrogen include Ammoniacal-nitrogen, Nitrite-nitrogen and

Nitrate-nitrogen. |

|||

All leachate levels and effluent

quality monitoring results were below the Limit Levels in the reporting period.

No action is thus required to be undertaken in accordance with the Event and

Action Plan presented in Annex

F3.

According to the updated EM&A Manual of the Project with

incorporation of the proposed updates under the Amendment Summary approved by

EPD on 15 June 2020, groundwater monitoring was carried out at 14 perimeter

groundwater monitoring wells (including 3 up-gradient wells and 11

down-gradient wells) (i.e. MWX-1 to MWX-14) to monitor the groundwater quality

and level of the perimeter groundwater monitoring wells at monthly interval.

The Limit Levels for groundwater quality is provided in Table

2.27 below.

Table 2.27 Limit Levels for Groundwater Quality

|

Location |

Limit Levels |

|

|

Ammoniacal-nitrogen (mg L-1) |

COD (mg L-1) |

|

|

MWX-1 |

5.00 |

30 |

|

MWX-2 |

5.00 |

30 |

|

MWX-3 |

5.00 |

30 |

|

MWX-4 |

7.63 |

36 |

|

MWX-5 |

5.00 |

30 |

|

MWX-6 |

5.00 |

46 |

|

MWX-7 |

6.55 |

36 |

|

MWX-8 |

15.85 |

50 |

|

MWX-9 |

7.30 |

71 |

|

MWX-10 |

5.00 |

30 |

|

MWX-11 |

5.00 |

30 |

|

MWX-12 |

5.00 |

30 |

|

MWX-13 |

5.00 |

30 |

|

MWX-14 |

5.00 |

30 |

A bladder pump with Teflon sampling

tube and adjustable discharge rates was used for purging and taking of groundwater

sample from the monitoring wells. Filtered groundwater samples were collected

by connecting a disposable in-line filter system to the tubing of the sampling

pump, prior to storage and analysis by ALS Technichem

(HK) Pty Ltd. (HOKLAS Registration No. 066). A portable dip meter with

5mm accuracy was used for measurement of groundwater level at each well.

The dip meter has an audio indicator of the water level and was checked before

use.

The measurements of pH and electrical conductivity (EC) were

undertaken in situ. In situ monitoring instruments in

compliance with the specifications listed under Section 4.3.2 of the updated

EM&A Manual were used to undertake the groundwater quality monitoring for

the Project. Details of the equipment used and

the monitoring locations are summarised in Table

2.28 and illustrated in Figure 2.1, respectively. Copies of the

calibration certificates for the equipment are presented in Annex F7.

Table 2.28 groundwater monitoirng details

|

Location |

Frequency |

Parameter |

Monitoring Dates |

Equipment |

|

|

All groundwater monitoring wells (MWX-1 to MWX-14) |

Monthly |

· Water level · pH · EC · COD · BOD5 · TOC · Ammoniacal–nitrogen · Nitrate-nitrogen · Nitrite–nitrogen · TKN · TN · Sulphate · Sulphide · Carbonate · Bicarbonate · Phosphate |

· Chloride · Sodium · Potassium · Calcium · Magnesium · Nickel · Manganese · Chromium · Cadmium · Copper · Lead · Iron · Zinc · Mercury · Boron |

5 August 2024 |

Horiba U-52G (S/N: NVAE08GT) |

The schedule for groundwater quality monitoring during the

reporting period is provided in Annex

C.

The groundwater quality monitoring results and detailed

monitoring results are summarised in Table 2.29

and provided in Annex F8,

respectively.

Table 2.29 Summary of Groundwater Monitoring Results in the

Reporting Period

|

Location |

Ammoniacal-nitrogen (mg L-1) |

COD (mg L-1) |

||

|

Monitoring Results |

Limit Levels |

Monitoring Results |

Limit Levels |

|

|

MWX-1 |

0.1 |

5.00 |

7 |

30 |

|

MWX-2 |

0.59 |

5.00 |

8 |

30 |

|

MWX-3 |

0.8 |

5.00 |

15 |

30 |

|

MWX-4 |

0.51 |

7.63 |

14 |

36 |

|

MWX-5 |

0.23 |

5.00 |

11 |

30 |

|

MWX-6 |

3.15 |

5.00 |

40 |

46 |

|

MWX-7 |

6.92 |

6.55 |

45 |

36 |

|

MWX-8 |

3.97 |

15.85 |

30 |

50 |

|

MWX-9 |

0.45 |

7.30 |

<20 |

71 |

|

MWX-10 |

N/A (a) |

5.00 |

N/A (a) |

30 |

|

MWX-11 |

<0.01 |

5.00 |

4 |

30 |

|

MWX-12 |

<0.01 |

5.00 |

3 |

30 |

|

MWX-13 |

0.03 |

5.00 |

2 |

30 |

|

MWX-14 |

0.01 |

5.00 |

4 |

30 |

|

Note: (a) Monitoring well MWX-10

is under maintenance. |

||||

Limit Level exceedances were recorded

for groundwater monitoring in the reporting period and actions in accordance

with the Event and Action Plan presented in Annex F3 were undertaken. Based on the investigation

conducted for the monitoring event with potential Limit Levels exceedance with

the Contractor and the IEC, the groundwater (Ammoniacal-nitrogen and COD)

exceedances at MWX-7 on 5 August 2024 were considered non

Project related.

The Contractor was reminded to implement all relevant

mitigation measures for the construction and operation works and maintain good

site practice. The ET will keep track on the monitoring data and ensure

Contractor’s compliance of the environmental requirements.

According to the updated EM&A Manual of the Project,

landfill gas monitoring was carried out at the perimeter of the waste boundary

(monitoring wells), area between the SENTX Site boundary and the waste boundary

(surface emission), occupied on-site building, service voids, utilities pit and

manholes in the vicinity of the SENTX (build-up of landfill gas) during the

operation/restoration phase.

The Limit Levels for landfill gas monitoring is provided in Table

2.30 below.

Table 2.30 Limit Levels for Landfill Gas Constituents

|

Parameters |

Monitoring Location |

Limit Level (% (v/v)) |

|

|

Perimeter Landfill Gas Monitoring Wells (a)

|

|||

|

Methane & Carbon Dioxide |

|

Methane |

Carbon Dioxide |

|

LFG1 |

1.0 |

3.2 |

|

|

LFG2 |

1.0 |

4.3 |

|

|

LFG3 |

1.0 |

6.3 |

|

|

LFG4 |

1.0 |

7.0 |

|

|

LFG5 |

1.0 |

3.4 |

|

|

LFG6 |

1.0 |

9.1 |

|

|

LFG7 |

1.0 |

1.5 |

|

|

LFG8 |

12.6 |

2.4 |

|

|

LFG9 |

2.5 |

1.7 |

|

|

LFG10 |

3.5 |

1.6 |

|

|

LFG11 |

3.0 |

2.0 |

|

|

LFG12 |

13.2 |

1.5 |

|

|

LFG13 |

22.5 |

2.7 |

|

|

LFG14 |

5.2 |

1.8 |

|

|

LFG15 |

18.2 |

2.0 |

|

|

LFG16 |

1.0 |

2.0 |

|

|

LFG17 |

17.8 |

2.4 |

|

|

LFG18 |

2.3 |

2.1 |

|

|

LFG19 |

6.3 |

3.1 |

|

|

LFG20 |

1.0 |

4.6 |

|

|

LFG21 |

1.0 |

4.8 |

|

|

LFG22 |

1.0 |

4.0 |

|

|

LFG23 |

1.0 |

10.3 |

|

|

LFG24 |

1.0 |

4.7 |

|

|

GP1 |

1.0 |

10.6 |

|

|

GP2 (shallow) |

1.0 |

11.4 |

|

|

GP2 (deep) |

1.0 |

10.4 |

|

|

GP3 (shallow) |

1.0 |

6.9 |

|

|

GP3 (deep) |

1.0 |

5.6 |

|

|

GP4 (shallow) |

1.0 |

11.6 |

|

|

GP4 (deep) |

1.0 |

7.7 |

|

|

GP5 (shallow) |

1.0 |

10.8 |

|

|

GP5 (deep) |

1.0 |

7.5 |

|

|

GP6 |

1.0 |

8.4 |

|

|

GP7 |

1.0 |

4.5 |

|

|

GP12 |

1.0 |

2.3 |

|

|

GP15 |

1.0 |

2.2 |

|

|

P7 |

1.0 |

2.5 |

|

|

P8 |

1.0 |

1.7 |

|

|

P9 |

1.0 |

2.7 |

|

|

Service Voids, Utilities Pits and Manholes |

|||

|

Methane (or flammable gas) |

Service voids, utilities pits and manholes |

1% by volume |

|

|

Permanent Gas Monitoring System |

|||

|

Methane (or flammable gas) |

Permanent Gas Monitoring System |

1% by volume (20% LEL) |

|

|

Area Between the SENTX Site Boundary and Waste

Boundary (Surface Emission) |

|||

|

Flammable gas |

Area between SENTX site boundary and waste boundary |

30 ppm |

|

|

Note: (a) Limit Levels established based on

the pre-operation phase baseline and additional landfill gas monitoring

results in the Pre-operation Baseline Monitoring Report. |

|||

Gas analysers

in compliance with the specifications listed under Section 5.4.1 of the updated

EM&A Manual were used to monitor the gas parameters at the landfill gas

monitoring wells, service voids, utilities pits and manholes. The gas analyser was calibrated by a laboratory accredited under

HOKLAS at yearly intervals and checked before use to ensure the validity and

accuracy of the results. A portable dip meter was used to monitor the water

level in the monitoring wells.

Permanent gas monitoring systems with pre-set alarm

levels for methane at 20% lower explosive limit (LEL, equivalent to 1% methane

gas (v/v)) were installed and operated in all occupied on-site buildings at

SENTX. A central control panel is equipped to alert site personnel when

the gas concentration at any detector reaches the alarm level.

The equipment used in the

landfill gas monitoring programme is summarised in Table 2.31. The landfill

gas monitoring locations for perimeter landfill gas monitoring wells, flammable

gas surface emission survey route and service voids, utilities and manholes

along the Site boundary are illustrated in Figures 2.3-2.4

and Annex G1, respectively.

Copies of the calibration certificates for the equipment are presented in Annex G2. The

flammable gas surface emission survey route has been reviewed and updated

against the latest construction/ operation programme

and approved by EPD on 17 June 2024.

Table 2.31 Landfill Gas Monitoring Details

|

Monitoring Location |

Frequency |

Parameter |

Monitoring Dates |

Equipment |

|

Perimeter landfill gas monitoring

wells (LFG1 to LFG24, P7 to P9, GP1 to GP7, GP12 and GP15) |

Monthly |

Ÿ

Methane Ÿ

Carbon dioxide Ÿ

Oxygen Ÿ

Atmospheric pressure |

13 Aug 2024 |

GA5000 (S/N: G507306) |

|

Service voids, utilities and manholes along the Site

boundary and within the SENTX Site (UU1 to UU28) |

Monthly |

Ÿ

Methane Ÿ

Carbon dioxide Ÿ

Oxygen |

7 Aug 2024 |

GA5000 (S/N: G507306) |

|

Permanent gas monitoring system in all occupied

on-site buildings |

Continuous |

Methane (or flammable gas) by permanent gas monitoring

system |

1 – 31 Aug 2024 |

Permanent gas monitoring

system |

|

Areas between the SENTX Site boundary and the waste

boundary and location of vegetation stress |

Quarterly |

Flammable gas emitted from the ground surface |

22 Aug 2024 |

GMI Leak Surveyor (S/N:

554846) |

|

Bulk gas sampling at least 2 of the perimeters LFG

monitoring wells |

Quarterly |

Ÿ

Methane Ÿ

Carbon dioxide Ÿ

Oxygen Ÿ

Nitrogen Ÿ

Carbon monoxide Ÿ

Other flammable gas |

13 Aug 2024 |

Gas sampling pump and Tedlar bags |

The schedule for landfill gas monitoring during the

reporting period is provided in Annex

C.

The landfill gas monitoring results are summarised

and provided in Tables 2.32 - 2.35 and Annex G3, respectively.

Table 2.32 Summary of

Landfill Gas Monitoring Results at Perimeter LFG Monitoring Wells in the

Reporting Period

|

Location |

Methane (% (v/v)) |

Carbon Dioxide (% (v/v)) |

||

|

Monitoring Results |

Limit Levels (a)

|

Monitoring Results |

Limit Levels (a) |

|

|

LFG1 |

0.2 |

1.0 |

1.7 |

3.2 |

|

LFG2 |

0.2 |

1.0 |

1.0 |

4.3 |

|

LFG3 |

0.2 |

1.0 |

0.1 |

6.3 |

|

LFG4 |

0.1 |

1.0 |

0.0 |

7.0 |

|

LFG5 |

0.1 |

1.0 |

0.1 |

3.4 |

|

LFG6 |

0.1 |

1.0 |

0.2 |

9.1 |

|

LFG7 |

0.0 |

1.0 |

0.0 |

1.5 |

|

LFG8 |

0.0 |

12.6 |

0.1 |

2.4 |

|

LFG9 |

0.0 |

2.5 |

0.0 |

1.7 |

|

LFG10 |

0.0 |

3.5 |

0.0 |

1.6 |

|

LFG11 |

0.0 |

3.0 |

0.0 |

2.0 |

|

LFG12 |

0.0 |

13.2 |

0.0 |

1.5 |

|

LFG13 |

0.0 |

22.5 |

0.0 |

2.7 |

|

LFG14 |

0.3 |

5.2 |

0.0 |

1.8 |

|

LFG15 |

0.3 |

18.2 |

0.5 |

2.0 |

|

LFG16 |

0.0 |

1.0 |

0.5 |

2.0 |

|

LFG17 |

1.1 |

17.8 |

2.8 |

2.4 |

|

LFG18 |

0.0 |

2.3 |

0.2 |

2.1 |

|

LFG19 |

0.0 |

6.3 |

0.0 |

3.1 |

|

LFG20 |

0.0 |

1.0 |

0.0 |

4.6 |

|

LFG21 |

0.0 |

1.0 |

0.0 |

4.8 |

|

LFG22 |

0.0 |

1.0 |

0.0 |

4.0 |

|